Inspecting the air source process and making certain good filtration also can support avert issues with pneumatic valves. Employing a preventive maintenance plan can help in determining possible problems ahead of they escalate, Hence cutting down downtime and dear repairs.

The valves that are applied to manage the pressure, route, and stream fee of compressed air are named pneumatic valves. Pneumatic methods trust in the pressure of compressed air to transmit ability and are available in plenty of purposes, like power resources for diesel engines.

For complicated air circuits that demand numerous and sequential operations of products, the valve of decision will usually be solenoid operated.

We’ve also talked over long run trends in pneumatic valve technological innovation, such as the event of good valves and IoT integration.

The main number indicates the amount of ports within the valve, and the next number implies the number of switching positions. As an illustration, a two/two-way pneumatic valve is usually a valve with two switching positions and two ports.

The spring/diaphragm pneumatic actuator includes a diaphragm and plate which are linked to an actuator stem. A flexible diaphragm is enclosed in pressure-tight housing.

As we discussed higher than, the pneumatic devices normally use compressed air to complete do the job. By managing this air in the procedure, we can certainly convert Electrical power into controlled motion. These pneumatic valves are crucial in pneumatic systems and perhaps hydraulic techniques.

Poppet type valves have a simple structure that make use of a encounter seal that opens and closes (often that has a spring return) in opposition to a valve seat. These valves offer better movement but can only be shifted to 2 positions. They can be much less popular than spool sort valves and are often utilised in more harsh environments.

Modular wiring is often applied with manifold mounted valve configurations. This wiring commonly contains a D-sub connector embedded while in the manifold base. This gives an effective and clean integration selection for substantial pneumatic programs.

These valves often serve certainly one of two functions. The very first activates a method when a particular stress is reached. The second helps prevent destruction by protecting the move amount inside the method or by releasing pressure when an too much amount is achieved.

Pneumatic directional Regulate valves play a crucial function while in the Procedure of pneumatic cylinders, which happen to be key components in different industrial automation programs. These valves exactly Regulate the stream hop over to here of compressed air into and outside of pneumatic cylinders, thus running the motion and positioning with the cylinder's piston.

Positioner and Accessories Pneumatic Management valves normally demand positioners and components to attain exact Regulate and modulation of flow. Mastering the selection and integration of positioners, air sets, together with other accessories is vital for optimizing the effectiveness and responsiveness of pneumatic Command valves.

There are several situation exactly where an air circuit designer could want air to become flowing by way of a specific valve once the circuit is turned off, and in Those people circumstances, may possibly specify a two-two N.O. click this site air valve.

Right integration with the pneumatic valve into your industrial process is important for maximizing its efficiency and longevity. Adherence to producer recommendations and business standards during set up is paramount.

Kelly McGillis Then & Now!

Kelly McGillis Then & Now! Michelle Pfeiffer Then & Now!

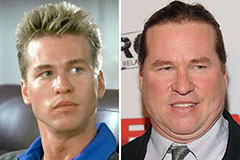

Michelle Pfeiffer Then & Now! Val Kilmer Then & Now!

Val Kilmer Then & Now! Mackenzie Rosman Then & Now!

Mackenzie Rosman Then & Now! Mike Smith Then & Now!

Mike Smith Then & Now!